Welcome Back!

Welcome back to my series on automation across different design fields! Today, let’s explore the pharmaceutical industry. Here, being precise and efficient is crucial. If you’ve followed my series, you know how automation improves things in apparel design and production. Did you miss a discussion on how to generally boost efficiency? Catch up here.

Why Pharma Packaging?

This post focuses on a critical part of pharmaceuticals: packaging design. Automating this part of the process helps companies work faster and make fewer mistakes. I will share a story about one company that changed its operations for the better by using new automation techniques.

Discover how these strategies can transform your business. Whether you’re a seasoned expert in the pharma industry or simply curious about the benefits of automation, this post is designed just for you.

Now, let’s look at a practical example of these benefits in action.

One Story of Pharma Packaging Automation

Meet Pavel Popovic—a pharma packaging automation expert whose experiences illuminate the path from concept to implementation.

Pavel is a forward-thinking designer and developer in the pharmaceutical packaging industry. He recognized a significant opportunity to boost efficiency and sought automation solutions for routine tasks. During his search, Pavel came across my MockUpinator script. This tool was close to what he needed but required some fine-tuning for his project.

Pavel reached out to collaborate, and we tailored it to suit better the tasks he aimed to automate. However, Pavel didn’t stop there; he expanded his automation efforts to include an entire workflow. Additionally, Pavel also tweaked my barcode script and developed his own Laetus Pharma Code Generation.

Key Innovations by Pavel:

Laetus Pharma Code Generation: Pavel created this script to automate the generation of essential Pharma Codes in Adobe Illustrator. This tool saves designers considerable time and significantly improves accuracy.

MockUpinator for Box Cut Creation: I originally crafted this script, and Pavel further enhanced it and adjusted it to his needs. In the Zentiva version, the script not only automates the creation of box die-lines for precise dimensions, but it also ensures consistent placement of design elements thanks to Pavel’s enhancements.

These advanced tools have reformed Pavel’s team’s operations, dramatically speeding up the design process and minimizing errors. The result isn’t just faster production—it’s about consistently delivering high-quality outcomes.

Watch the video below to understand better how these tools function in the real world. Pavel demonstrates the enhanced efficiency and precision these automation tools bring to pharmaceutical packaging design.

Let’s dive deeper into how each part of the process unfolds:

Process Step by Step

- Create a Box: The process begins by using the MockUpinator to automatically generate the box structure, including all necessary cut-outs and fold lines according to specified dimensions.

- Place Artwork: The next step is moving the artwork once the box structure is ready. The script intelligently places each design element on the appropriate side of the box, ensuring there are correct gaps to the edges to maintain design integrity and print quality.

- Add Barcodes: Afterwards, a designer can add all necessary barcodes, such as EAN-13, UPC-12 or Laetus Pharma Code Generation script. This automation ensures accuracy in the vital identifiers required for pharmaceutical products. (The part with generating barcodes is not on the video)

Managing these detailed processes efficiently requires robust workflow management. Here’s how Pavel organizes and controls these automated tasks:

Smart Workflow Management

As you can see in the video, Pavel has neatly organized the various workflows in the panel on the left. This is an excellent method for managing your scripts efficiently. There are different tools available online for this purpose. In this case, Pavel utilizes the free Scripshon Trees plugin. This way, you can store it in a remote cloud directory. This setup is functional because it automatically updates scripts or adds new ones on all organizational computers whenever changes are made.

This efficient workflow significantly reduces manual labour, minimizes errors, and accelerates the packaging design process, allowing Pavel’s team to increase productivity.

The Impact of Automation on Pavel’s Workflow

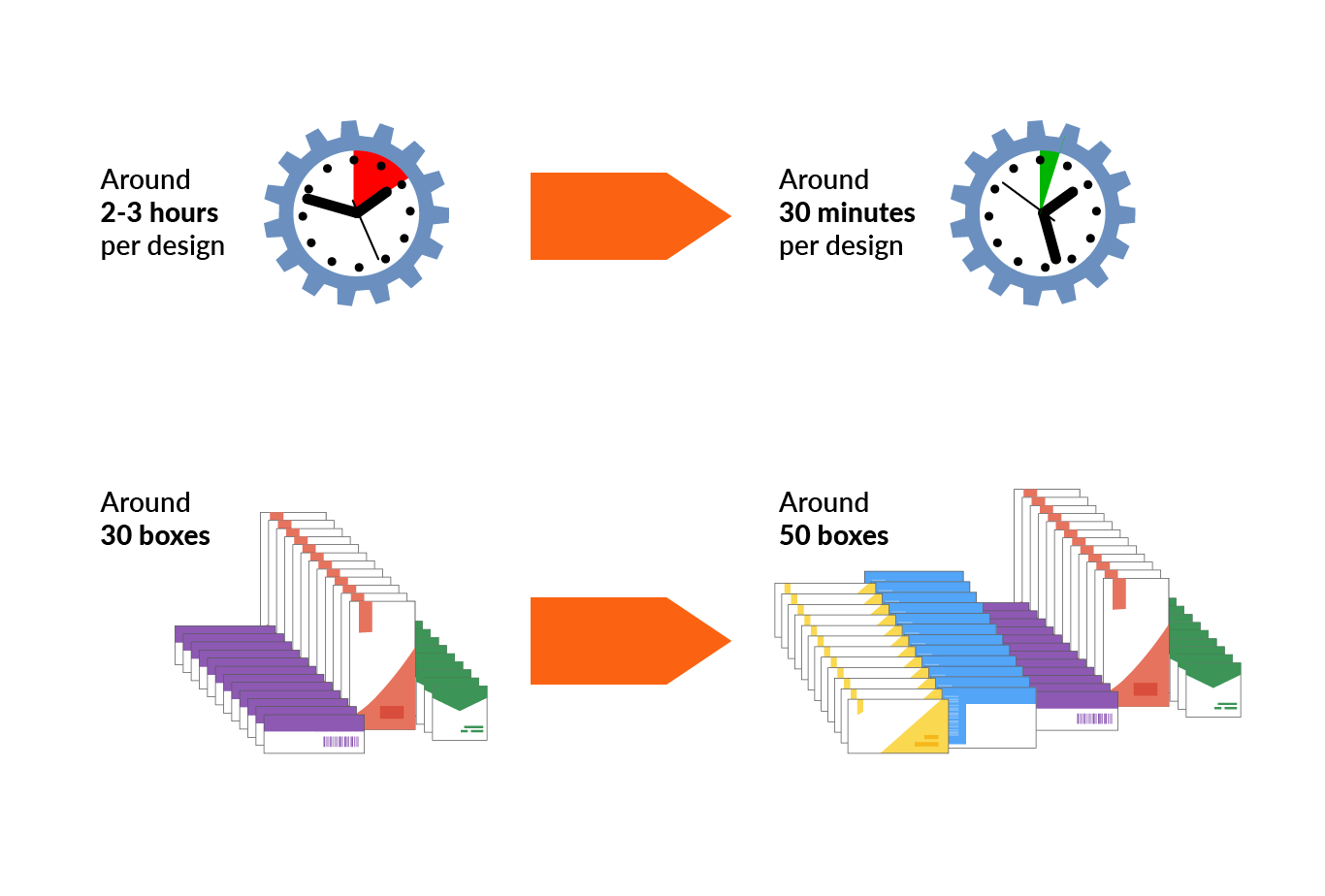

Implementing automation into workflow has significantly boosted the team’s efficiency. Before automation, the process from concept to ready-to-print files could take several hours per design. Now, with tasks such as box creation and insertion of layout and Pharma Code automated, this time has been dramatically reduced to just a fraction of what it was. Specifically, where it once took 2-3 hours to produce a single packaging design, it now takes only 30 minutes. This efficiency gain allows Pavel and his team to handle more projects—increasing their output from 30 boxes per week to 50. The ability to manage more projects with greater precision has improved overall productivity and enhanced the team’s capability to meet tight deadlines more effectively.

Overcoming Adoption Challenges

The biggest challenge Pavel faced with automation was people. Educating the team to adopt new working methods proved difficult, as old habits die hard and sometimes lead to mistakes. To tackle this, Pavel took proactive steps. He created detailed manuals and instructional videos to guide his team through the new processes. Every new employee is required to study these materials as part of their onboarding. Despite these efforts, Pavel acknowledges that the transition remains challenging, but continuous education and training are essential to smoother operations.

While tackling these challenges, Pavel continues to look forward, identifying areas for further improvement such as refining error handling in packaging.

Refining Error Handling in Packaging

Pavel mentioned another area he aims to enhance: error management. Despite automation, errors still occur because many tasks involve human input. All packaging text sourced from official regulatory authorities must be checked and approved by them. If they find mistakes, the artwork is sent back for corrections. Even after packaging receives approval, changes can arise during production. While automation has improved this process, it hasn’t completely eliminated errors. So, there is room for further refinement to make the system even more efficient.

Embracing the Future of Pharma Packaging Design

In conclusion, our journey through the automation of pharmaceutical packaging has not only revealed the significant benefits but also highlighted the ongoing challenges. By integrating tools like the MockUpinator and Laetus Pharma Code Generation, Pavel’s team has seen a dramatic increase in efficiency and accuracy, showcasing the transformative power of automation.

This experience, along with my own, emphasizes the need for visionary leadership in the adoption of automated processes. Having someone who can foresee the potential of automation and guide the team towards that future is crucial.

As we continue to refine our processes and explore new technologies, the potential for even greater improvements is vast. Whether it’s in pharmaceuticals, cosmetics, or food packaging, precision is critical, and automation plays a pivotal role in achieving it.

Thank you for joining me on this exploration of automation’s possibilities. If you’re curious about how these innovations could benefit your business or if you want to share your automation experiences, I am eager to engage with you. Let’s discuss how we can leverage these powerful tools to enhance your operations and unleash your creative potential.

I hope this series inspires you to consider what automation can achieve for your business. Together, llet’smake your operations more efficient and innovative.

2 Responses